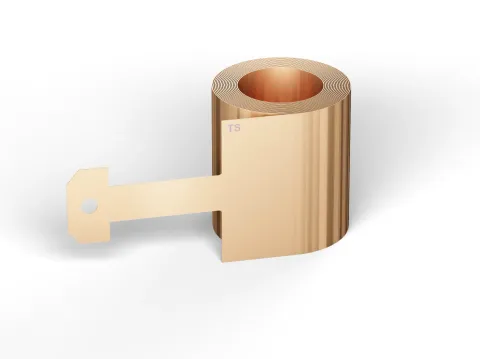

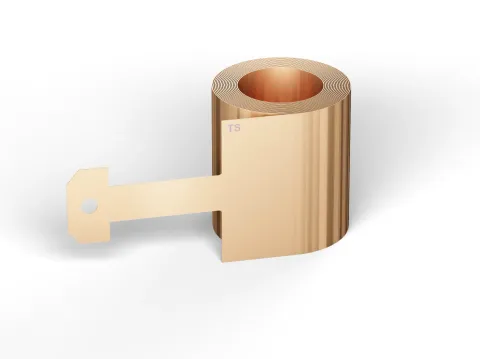

Constant Force Springs are generally constructed as a pre-stressed flat strip material that is tightly wrapped around a drum or shaft in the center and the hole in the free end is attached to a loading force like a counterbalance application. As the spool is unwound (deflected), it exerts a near constant force because the geometry of the coil remains nearly constant by the drum.

TSMC’s constant force springs offer a number of user benefits: include a constant load at a zero rate, a smooth range of motion, strong force yield within small spaces, extremely long linear extensions possible and store power indefinitely when extended... The constant force spring is an excellent design component for applications where a constant load is required.

Basically, the length, material thickness, width, the diameter of the coil and the natural radius curvature all contribute to extension resistance (affect the spring’s load). Additional flexibility in load can be increased by using multiple constant force springs with spool, tandem, laminar, back to back, cavity ,pulley mounting or in other configurations to suit the design situation. The full rated load of the spring is reached after being deflected to the length extended to 1.25 times its diameter.

Our constant force springs can be used in many applications include systems that require retraction like cable retractors, door closers, power cords, tape measures, window regulator mechanisms, hose retrievers, space vehicles, gym equipment, counterbalances, toys, electric motors, hair dryers, and other long-motion functions. Also our talent engineer can custom design and manufacture an end fitting for your application

FEATURES

Roll back the force (zero gradient).

When stretched to a length of 1.25 times the outside diameter, a fixed force is achieved.

There is no friction between the coils (acting smoothly).